Our release pads are based on unique hydrophobic membrane technology and are in the

process of being patented. We have created unique multi-layer membranes from which Sulphur

dioxide gets released when exposed to moisture vapour. Our actual field studies over the past

few years in actual refrigeration conditions and research conducted and certified by NRCG, a

recognized Grape testing body of the government of India have proven that our product is well

suited to act as a Grape guard to protect the grapes during transportation and storage.

Special technology is adopted in incorporating the Sodium metabisulfite, which acts as a

SO2 release agent. These are not particulate deposits and hence no residue is found on the

berries as you will find in all the commonly used Grape Guards..

Extremely low particles of SO2 emitter is formed and applied on to a backing support.

Because of this the surface area of the emitter increases multifold and thus provides high

efficiency in the release of the SO2 gas unlike other products. This not only curtails the Sodium

metabisulfite content in our composition, without having deleterious effect and efficacy of the

product but also reduces overall pollution of the product as disposal of unused Sodium

metabisulfite is a big issue as it can attack plant organisms..

Our product maintains consistent pH over its long period of usage. Studies have shown

that constant pH results in constant release of SO2 gas. Tests show that there is no control in pH

in many of the products available in the market. Inconsistent release of SO2 gas causes problems

like bleaching of the berries, fungal attack, Sulphur injuries etc.

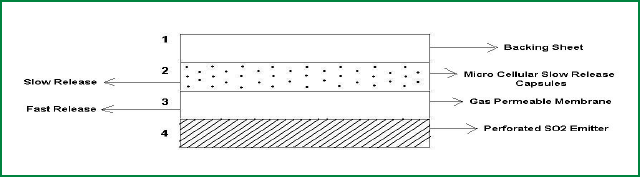

• Freshguard multi stage controlled release sheet is composed of 4 layers:

1. The first layer is a backing sheet with details printed on the top.

2. The second layer has active content with microcellular slow release capsules. This layer

emits a controlled constant slow release of SO2 gas for a long period.

3. The third layer is composed of a special gas permeable membrane. This layer acts as fast

release of SO2 gas and prevents fungal decay in the initial stages of storage. The gas

permeable membrane allows a controlled release of SO2 gas from layer 2 in longer

storage durations.

4. The fourth layer is a perforated SO2 emitter which helps to emit the SO2 gas without

actual contact of the active material causing no harmful effects on the fresh produce.

C-14, MIDC Area, Ambad, Nashik-422 010.

Phone : +91-2536600208 / 6601209

Email : freshguard@magmapolymers.in

magmapolymerspvtltd@gmail.com